EXPANSION JOINT

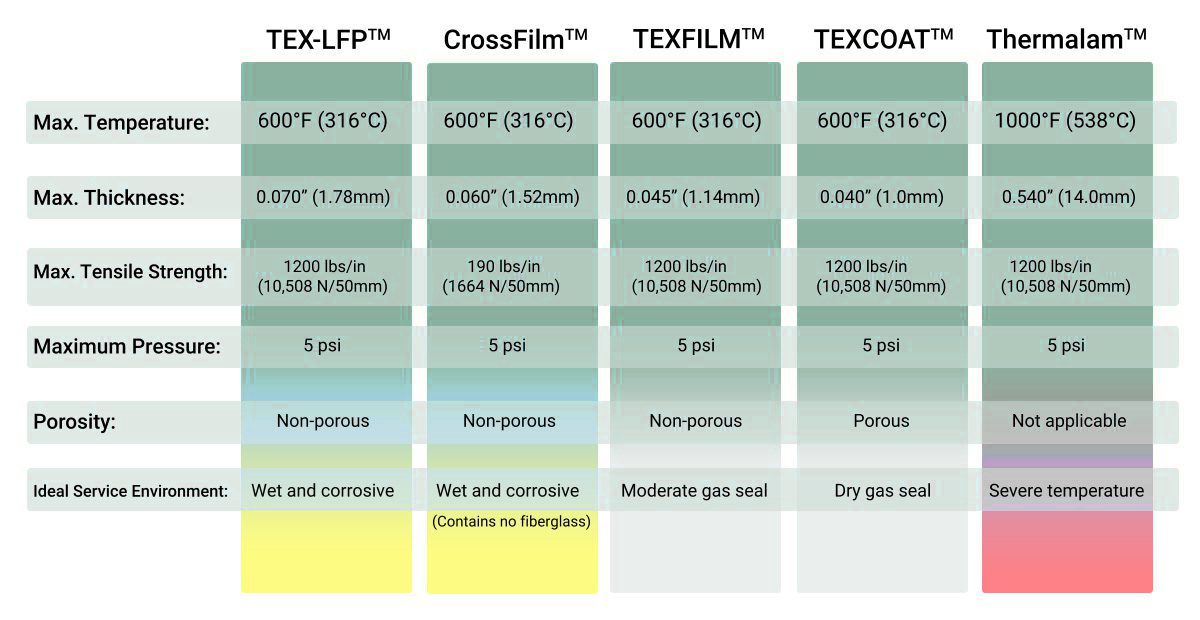

TCI is the leading global supplier for high-quality, non-metallic, fabric expansion joint materials to fit a variety of service needs. Our 100% PTFE materials, as well as our PTFE composites and laminates, are engineered to provide optimal performance as flexible fabric expansion joints over a long period of service. Fabric expansion joints, also known as flue ducts or fabric bellows compensators, made from our materials are highly resistant to extreme temperatures, chemical attack, and typical wear and tear. TCI’s fabric expansion joint materials are equipped to survive in extremely corrosive environments and severe temperature while remaining flexible enough to reduce stress at junctions. TCI provides a variety of different materials, including our 100%-PTFE CrossFilm™ material, to fit the gas conveyance needs of virtually every industry.

Gas Seal Expansion Joint Service

General Purpose Expansion Joint Service

TEXFILM™ 1005: This cost-effective expansion Joint material has been engineered for moderate duty flue gas service.

Challenging Expansion Joint Service

TEXFILM™ 1009: Laminated PTFE/Fiberglass composite engineered for challenging gas seal service.

TEX-LFP™ 14-7: Expansion joint material possessing the exceptional, impervious, properties of CrossFilm™ barrier and the ruggedness of a PTFE/Fiberglass Composite.

CrossFilm™ 2160: 100% PTFE laminate engineered for challenging chemical/thermal expansion joint applications.

CrossFilm™ 2105: Expansion Joint Material is an exceptionally thin, high strength, PTFE laminate that has been targeted for challenging thermo/chemical applications.

Light Duty Expansion Joint Service

TEXFILM™ 404/2: this cost-effective expansion joint material has been engineered for light-to-moderate duty flue gas service.

High Temperature Expansion Joint Service

THERMALAM™ 50/1005: Single membrane PTFE/Fiberglass laminated Composite engineered for High Temperature Flue Gas Service.

Gas Seal Expansion Joint Service

General Purpose Expansion Joint Service

Challenging Expansion Joint Service

Light Duty Expansion Joint Service

High Temperature Expansion Joint Service

TEX-LFP™ materials possess the exceptional, impervious properties of their CrossFilm™ barrier and the ruggedness of their Texcoat™ load bearing component. The CrossFilm™ barrier is made solely of PTFE resins. A number of high strength plies of proprietary PTFE film are cross-plied, then laminated together, resulting in a chemical liner with multidirectional strength and exceptional durability. It is this unique combination that has made TEX-LFP™ the world's most popular choice for PTFE expansion joint products for the last 20 years.

Downloads

Data Sheets

TCI’s CrossFilm™ is a 100% PTFE material that is guaranteed corrosion and contamination free, resists tearing, and has superior flexing capabilities compared to other PTFE products. CrossFilm™ can be heat-sealed and is unaffected by UV exposure or moisture. Read more »

Downloads

- CrossFilm™ Technology Brochure

- Why CrossFilm™ for Expansion Joints?

- CrossFilm™ 2105 vs. Skived Film

- CrossFilm™ for FGD Service Expansion Joints

- CrossFilm™ Flex Test Brochure

Data Sheets

Texfilm™ is a nonporous composite consisting of a PTFE-coated fiberglass fabric and a CrossFilm™ barrier, which has been laminated to one side of the fabric. The thin, laminated film is a cost-effective approach to significantly improving the performance of a PTFE-coated fiberglass component when exposed to corrosive environments in non-metallic expansion joint applications.

A durable PTFE coating is applied to a rugged, continuous-filament fiberglass reinforcement. Three plies of high strength PTFE film are laminated to produce the CrossFilm™ barrier. The resulting PTFE barrier is rugged, flexible, and stress crack resistant. The typical thickness of film for a Texfilm product is 0.004" or 0.005". Variations can be engineered upon request.

Downloads

Data Sheets

Texcoat™ has been successfully used since 1985. This PTFE/fiberglass composite is engineered for high temperature, mechanically demanding service, with severe chemical and temperature exposure capabilities. The Texcoat™ product line is at home in food service and expansion joint applications which require extreme thermal conditions, harsh chemical environments, and where release or cleanability is essential. Special colors are available upon request. TCI manufactures Texcoat™ in different thicknesses to better serve your company's non-metallic expansion joint requirements.

Data Sheets

Thermalam™ is manufactured by laminating a nonporous PTFE/fiberglass composite to a fibrous textile layer generally made from fiberglass. The two components are fixed together using a proprietary high temperature fluoropolymer adhesive. Because the insulation mat is mechanically bonded to the outer cover component, it acquires the tensile and tear strength properties of Texfilm™ 1005. As a result, the service life of the high temperature Thermalam™ material is significantly extended. The single membrane construction also minimizes the formation of "hot spots" and greatly simplifies the installation of the expansion joint. Thermalam™ 50/1005 can perform in flue gas temperatures up to 1000°F (538°C) and can be fabricated into numerous expansion joint shapes and sizes.

Downloads

Data Sheets

Bias technology allows elongation of a fiberglass-reinforced product. With the typical square weave format of PTFE/fiberglass expansion joint materials, the maximum elongation is around 3%. Using the Bias format, however, an elongation percentage of over 30% can be achieved.

Downloads

The first flexible PTFE expansion joint product resistant to flue gas turbulence.

Downloads

Expansion Joint Signs Engineered for the most extreme environments.

Downloads

Cost-Effective and Easy-to-Use Heat Sealers Engineered for use on TCI's Materials.

Downloads

- Can You Trust Your Expansion Joint Material?

- Why CrossFilm™ for Expansion Joints?

- CrossFilm™ 2105 vs. Skived Film

- CrossFilm™ for FGD Service Expansion Joints

- CrossFilm™ Flex Test Brochure

- Expansion Joint Fabrication Solutions

- The Bias Format

- TEX-LFP™ Barrier Technology

- FEP & PFA Welding Grade Films

- Thermalam™ Advantages

- Power generation

- Pulp and paper plants

- Refineries

- Steel mills

- Foundries

- Smelters

- Cement plants

- Kilns

- Refuse incineration

- Marine

- Food processing

- Vapor/heat/dust recovery

Ready to get started with us?

Get the right service, determine what you need contact us for the most suitable services.